Castle & Pryor tackle challenging film set construction

As the UK film industry continues to expand with significant investments in new studios and infrastructure, local companies are finding opportunities to step into unique roles.

One recent project saw Castle & Pryor Ltd, a specialist in diamond drilling, concrete cutting, infrastructure, and aviation maintenance, take on the task of removing a large concrete water tank from a film set.

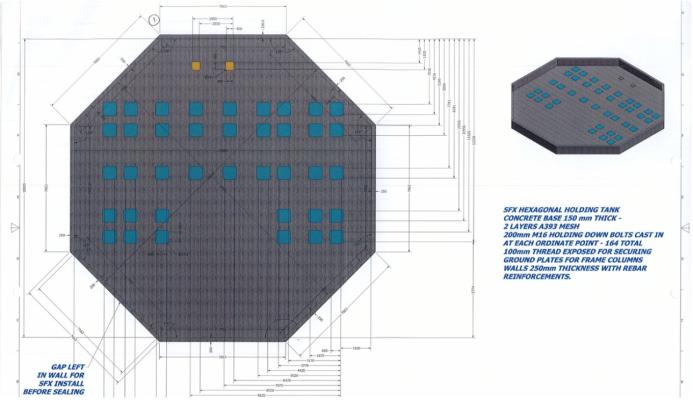

For a particular scene, the production required a hexagonal tank measuring 18m x 18m, with 1m high walls, 250mm thick, and a 150mm thick concrete floor slab. This tank was designed to hold water for a dramatic sequence where water crashes through a glass wall. Historically, such tanks were constructed from composite material sections bolted together, but this method was both costly and prone to leaks.

To address these issues, MTD Formwork, the company responsible for constructing the tank, opted for an in-situ concrete shell built on a protective polystyrene layer to prevent damage to the studio floor. The challenge, however, was how to dismantle this concrete structure once filming concluded, without disrupting ongoing studio activities.

Innovative Approach

Castle & Pryor faced tight constraints, as traditional demolition methods involving heavy machinery were unsuitable due to the noise and vibration they produce. Instead, the team employed a Diamond Sawing Technique to carefully cut the tank into sections that could be easily removed and disposed of off-site.

The process began with the removal of the tank walls. Using Tyrolit WSE 1217 and Husqvarna WS 482 track-mounted saws, horizontal cuts were made around the base of the walls, followed by vertical cuts at the wall ends. The sections were then lifted out by MTD Formwork using a telehandler and loaded onto flatbed lorries for disposal.

Next, the floor of the tank was segmented using a Husqvarna FS 7000 floor saw. The telehandler was again used to remove these sections. A Husqvarna K6500 Ring Saw was employed for any final cuts that the larger saws couldn’t reach. MTD Formwork managed water control during the cutting process with wet vac units provided by Castle & Pryor, collecting wastewater in site skips.

Successful outcome

The entire operation was completed within four days, ahead of the planned five-day schedule, and within budget. The film company expressed their satisfaction with the rapid and minimally disruptive work.

Castle & Pryor’s involvement in this project highlights their ability to adapt their expertise to meet the unique demands of the film industry, demonstrating how local businesses can contribute to the success of major productions.