Concrete strength sensing system wins Edison Award

The Purdue University, Indiana, US invention that could help reduce time and money spent on constructing and repairing concrete highway pavements and other structures has been recognized as a gold winner of an Edison Award in the Critical Human Infrastructure category.

The Edison Awards, considered the “Oscars of innovation,” are given annually to “recognize the persistence and excellence that also characterized Thomas Edison’s work.”

Previous winners include Honeywell, GoPro, General Motors and 3M. Purdue received its award last month (April) at the 2024 Edison Awards in Fort Myers, Florida.

The invention is sensors embedded into a fresh concrete pour that can measure the concrete’s strength levels in real-time, conveying when highway pavement is strong enough for traffic. These sensors are also being tested and developed for use in bridges, airport runways and buildings to reduce their need for repair and speed up construction timelines.

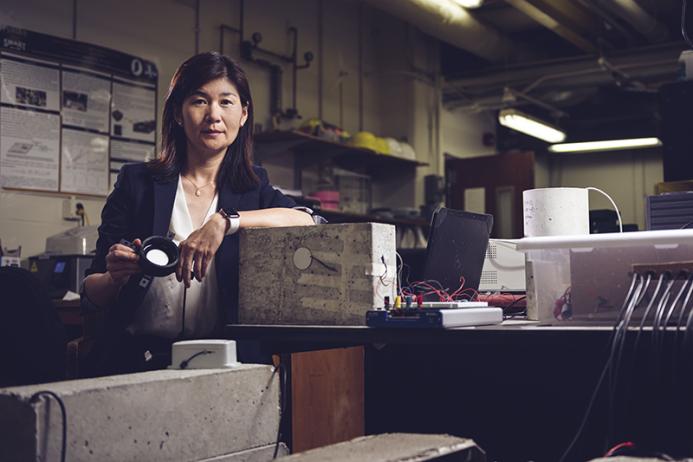

Luna Lu, Purdue’s Reilly professor of civil engineering, has led development of the sensor technology since 2017. Launched in December 2023, as the REBEL Concrete Strength Sensing System, a product of Wavelogix. Lu, the chief executive officer of Wavelogix, founded the startup in 2021.

According to the Federal Highway Administration, concrete pavement makes up less than 2% of U.S. roads but approximately 20% of the U.S. interstate system. Though concrete interstate pavement supports much of the nation’s traffic, road construction has caused traffic jams that waste 4 billion hours and 3 billion gallons (11 billion litres) of gas per year.

Using the REBEL Concrete Strength Sensing System could decrease the frequency of concrete pavement repairs and allow roads to open sooner after a fresh pour by providing a better understanding of the concrete’s strength levels and precisely determining when the pavement is strong enough to handle heavy traffic.

According to Wavelogix, the sensor system “may be the most effective alternative to concrete strength tests that have been in use for more than 100 years. Engineers would no longer have to test large samples of concrete at a lab or onsite facility to estimate the strength level that a concrete mix will reach after it’s been poured and left to mature.

“Rather, these sensors would be put into a concrete pour and plugged into a handheld device that logs concrete strength data, which provides the ability to directly monitor fresh concrete and accurately measure many of its properties at once.”

Highways and bridges using this technology, it said, could last longer, which would further reduce repairs, the traffic the repair work causes, and millions of taxpayer dollars spent on these repairs. Cutting down on traffic would also reduce carbon dioxide emissions that vehicles would have emitted while waiting to get around a construction site. In decreasing road repairs, the technology has the potential to reduce 1 billion tons of carbon emissions globally by cutting up to 20% of cement in concrete mixes.

More than half of U.S. states with concrete interstate pavement are currently participating in a Federal Highway Administration study to implement the sensor system, including Indiana, Missouri, North Dakota, Kansas, California, Texas, Tennessee, Colorado and Utah.