Reusable formwork cuts concrete use by 60%

A doctoral student from ETH Zurich has developed a foldable, reusable formwork system that reduces the environmental impact of concrete construction. Dubbed "Unfold Form," the lightweight moulds can reduce concrete use by up to 60% and steel by 90%, offering a sustainable alternative to conventional methods.

The system was created by architecture researcher Lotte Scheder-Bieschin, who sought to address the waste and emissions associated with traditional concrete floors. "I wanted a solution that uses strength through geometry, optimising both the formwork and the final structure," she explains.

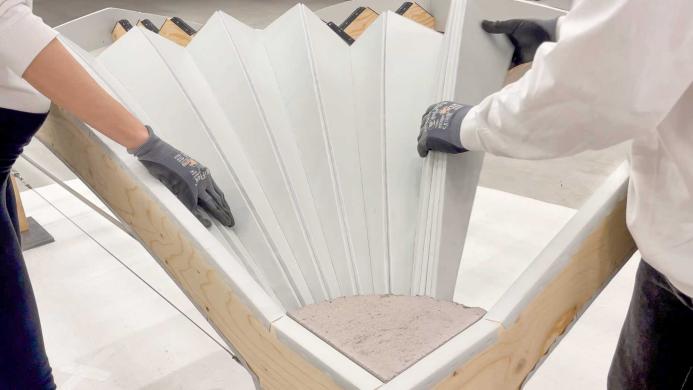

Unfold Form uses thin plywood strips connected by textile hinges, which can be folded and unfolded like a hand fan. Once assembled into a zigzag pattern, the formwork is sturdy enough to support up to a tonne of concrete but weighs only 24 kg. After the concrete cures, the mould can be folded away for reuse.

A Greener Approach

Concrete, a mixture of cement, water, sand, and gravel, is the world's most-used construction material but is highly carbon-intensive. Conventional concrete floors require steel reinforcement, adding to their environmental footprint. Unfold Form’s design eliminates the need for steel and uses significantly less concrete, addressing both sustainability and cost concerns.

ETH Zurich, located in Switzerland, is a globally renowned institution specialising in science and technology. The university’s Block Research Group (BRG), where Scheder-Bieschin conducts her research, focuses on reducing material use in construction. One of BRG’s notable innovations includes vaulted concrete floors, which inspired the design of Unfold Form.

Practical Benefits and Real-World Trials

The formwork is designed to be simple and cost-effective, requiring no advanced machinery or specialised skills. Its materials cost CF 650 (£578), and assembly can be done with basic tools, including a stapler and template. Scheder-Bieschin herself assembled a prototype while pregnant to demonstrate its accessibility.

The system has been tested in Switzerland and South Africa. A prototype was constructed on ETH Zurich’s campus, while another was built in Cape Town with the help of nonCrete, a local company focused on sustainable and affordable housing. The South African trial used bio-concrete made from shredded invasive vegetation, demonstrating that premium-grade concrete isn’t necessary.

Mark Hellrich, a scientific assistant on the project, transported the formwork to South Africa in two surfboard bags. “This shows how portable the system is,” says Scheder-Bieschin. The formwork maintained its quality after reuse and proved compatible with different concrete types.

Natural Inspiration

Unfold Form’s zigzag design draws from nature. The ribbed structure, inspired by seashells, provides extra stiffness without adding weight. This geometry strengthens both the formwork and the resulting concrete floor. The system uses curved-crease folding, an engineering technique adapted from origami, to achieve its unique shape.

“When you bend a single strip of material, it’s wobbly and hard to control,” Scheder-Bieschin explains. “But connecting curved edges between strips creates a stable structure. The zigzag pattern also shapes the concrete into a ribbed design, which improves load transfer.”

Next Steps

Scheder-Bieschin plans to expand her research and bring the system to market after completing her doctorate. She is currently working on designs for a market hall in Cape Town and aims to launch training programmes for local builders. “The goal is to help people construct their own sustainable buildings using this system,” she says.

ETH Zurich continues to lead in sustainability-focused research, offering innovative solutions for global challenges. This formwork system exemplifies how smart design can reduce resource consumption while supporting construction needs in both developed and developing regions.