HydroGraph patent offers potential in high-strength concrete

HydroGraph Clean Power Inc., a sustainable graphene producer based in Vancouver, has submitted two US patent applications for its innovative graphene-coated hollow glass microsphere (HGMS) technology. These developments could lead to significant advancements in lightweight, high-strength materials, especially in sectors such as automotive, marine, aerospace, and notably, construction.

The first patent covers HGMS coated with pristine graphene, while the second applies to reactive graphene-coated bubbles. HydroGraph’s new technology aims to enhance both sustainability and performance in material composites. The graphene-coated bubbles, developed using industrially available uncoated hollow glass bubbles, present a straightforward solution for lightweighting and strengthening applications. These coated microspheres have already attracted industry interest and could be used as a "drop-in" product in a range of materials.

One of the standout applications is in the construction industry. The graphene-coated bubbles have the potential to revolutionise the production of lightweight, high-strength concrete. By incorporating these coated microspheres into concrete mixes, builders can achieve stronger yet lighter materials, offering advantages in both performance and sustainability. This could be particularly beneficial for large-scale projects requiring advanced material properties without the added weight.

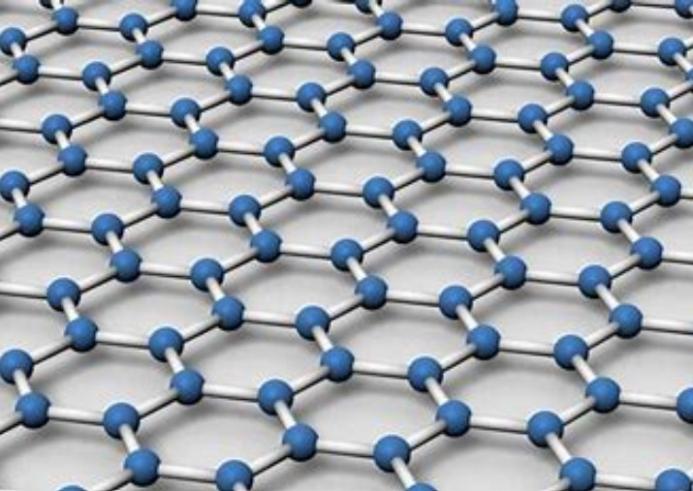

HydroGraph’s technology transforms the typical insulating white glass bubbles into black, electrically conductive, free-flowing powder through a nanoscale graphene coating. These bubbles are composed of thin glass shells, less than 100 microns thick, filled with air, making them exceptionally light—so much so that they can float on water. The lightweight and spherical structure of the bubbles is preserved with the graphene coating, while additional properties like electrical conductivity and potential filtration capabilities are introduced.

In addition to its construction applications, the coated microspheres are ideal for use in composites, such as electromagnetic interference (EMI) shielding or as lightweight fillers in plastic parts. The coating could also make these bubbles valuable in other industries, with estimates suggesting that the market for bare glass bubbles alone could reach $8 billion by 2024.

Kjirstin Breure, president and interim CEO of HydroGraph, said: “Our new patent applications show our commitment to expanding the possibilities of graphene technology. These innovations offer lightweight, high-strength materials that meet the evolving needs of industries like automotive, aerospace, and construction.”

HydroGraph has filed 11 patent applications globally and in the US, with two patents already granted for its pristine graphene manufacturing method.